Category

Product

Client

Location

In the dynamic realm of pharmaceutical manufacturing, the meticulous handling and inspection of critical components are paramount. PalPharma’s Hygienic Handling Equipment division has emerged as a trusted partner for pharmaceutical clients seeking ingenious solutions to streamline their processes and enhance product quality.

One of the primary challenges encountered involves the handling of elastomer stoppers used as closures in biomedical and infusion applications. PalPharma’s innovative Post-Hoists are providing a transformative answer to these challenges, ensuring seamless operations while maintaining stringent hygiene standards.

Pharmaceutical manufacturers often confront the intricate task of inspecting oral solid dosage forms, such as tablets and capsules, before they are packaged. The scrutiny involves assessing factors like embossed print accuracy, colour consistency, foreign body presence, size, and overall defects. Additionally, the production of elastomer stoppers used for sealing syringes, vials, and other containers demands impeccable handling and inspection due to their critical role in safeguarding the final parenteral drug form.

Recent times have witnessed a surge in inquiries from pharmaceutical and biopharmaceutical entities seeking hygienic solutions to handle bulk elastomer stoppers. These rubber bungs, crucial for maintaining sterility and preventing contaminants from entering sealed containers, undergo meticulous inspection and quality control processes. Manufactured within controlled cleanroom environments, these stoppers are subjected to rigorous safety measures, including gowning protocols, cleanroom adherence, and personnel/material control.

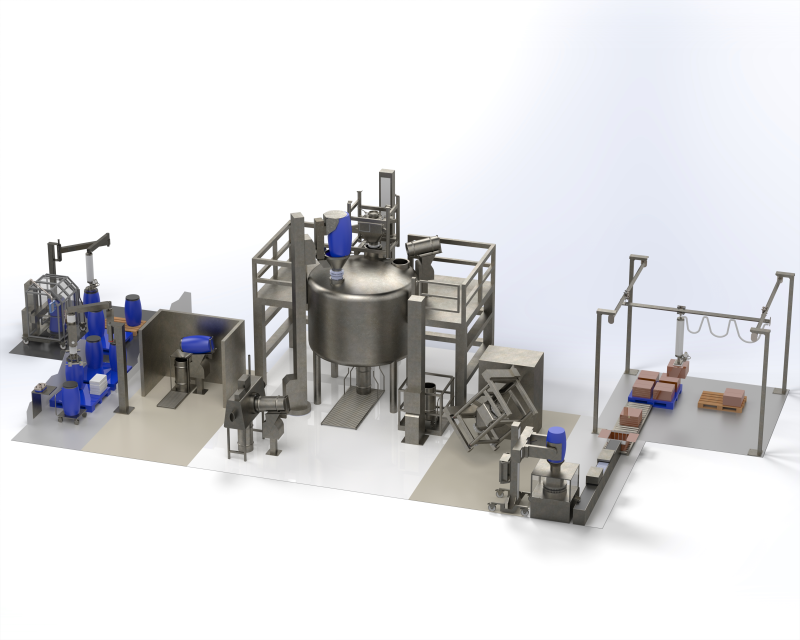

Palamatic’s engineers meticulously designed two IBC variants (for vision and post-treatment stages) equipped with hinged closure lids to mitigate cross-contamination risks. The stainless steel surfaces of the IBCs are treated with micro-undulation to reduce friction, ensuring efficient discharge of stoppers while maintaining impeccable corrosion resistance and cleanability. The integration of hygienic butterfly valves further ensures controlled and precise material flow.

As the world faces unprecedented challenges, PalPharma stands as a dedicated contributor to the pharmaceutical supply chain, particularly in the production of essential vaccines. The PalPharma Post-Hoists, with their impeccable design, comprehensive testing, and validation documentation, embody the commitment to excellence that defines PalPharma’s role in advancing pharmaceutical manufacturing.

The collaboration between PalPharma and its pharmaceutical clients exemplifies a harmonious synergy of innovation and precision. By addressing intricate handling and inspection challenges, PalPharma Post-Hoists are instrumental in ensuring the seamless and hygienic transfer of elastomer stoppers, safeguarding the integrity and quality of pharmaceutical products. As the global healthcare landscape evolves, PalPharma remains steadfast in its dedication to advancing pharmaceutical manufacturing practices and contributing to a healthier world.

Please enter your email for instant download of our Free Maintenance Guide.