Category

Product

Client

Location

In the realm of industrial operations, the demand for streamlined processes and adherence to stringent safety standards is paramount. As a response to the intricacies involved in opening and discharging 180 sacks of spices per batch, the imperative for complying with COSHH regulations, health and safety guidelines, and achieving improved process efficiency, the need for an innovative solution becomes evident.

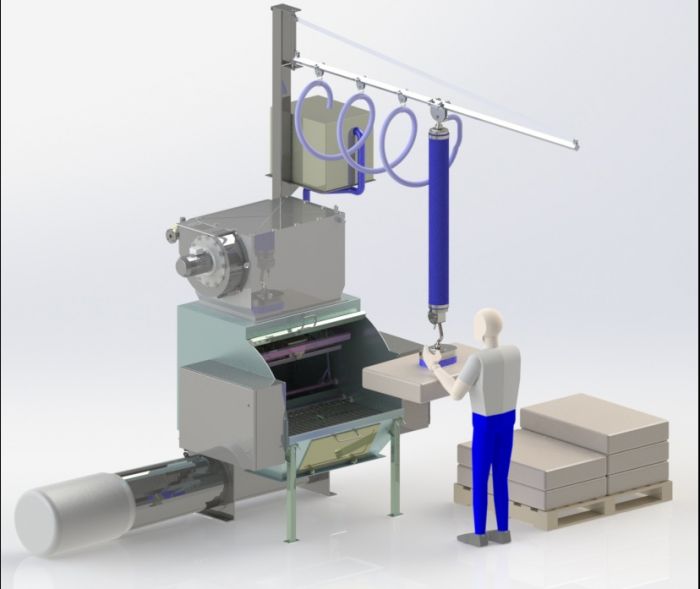

The PAL-FAST machine is a fully automatic solution for medium throughput sack discharging for up to 3-5 sack a minute. Ideal for food, pharmaceutical and chemical applications where production is discharged into a mixing process, all within a safe dust free environment without the need for manual cutting of sacks. The system is designed to prevent any contamination from the outer bag once the bag is inside the machine body thus keeping the product contamination free.

The operator can load the PAL-FAST -MF using a Palamatic Vacuum Tube lifter to lift the sacks. The door is manually closed which locks automatically starting the opening and emptying process and feeds the emptied sack into the waste sack compactor. The door automatically opens in readiness for the next sack to be loaded. The compact design of this machine ensures the neatest footprint and another important feature is that the product is never in contact with the outer sack.

If you’re looking to make your business’s material handling processes simpler, safer, and more efficient, then get in touch.

Website built by Fenti Marketing

Please enter your email for instant download of our Free Maintenance Guide.