Ergonomic Challenges in Aseptic Production Suites

In Aseptic production suites, we have witnessed numerous ergonomic issues associated with loading/unloading freeze dryers/lyophilizers, autoclaves, filling line inlets /outlets.

Challenges of Manual Handling

Taking ampoules/vials that can be either empty or filled residing on a tray – perhaps sitting within a multiple tray shelf with minimal distance between them – waiting to be transported to their next destination can pose ergonomic issues. These issues can be aggravated by the multiple layers of uncomfortable PPE that the operator must wear.

Image: Tray Loading Process

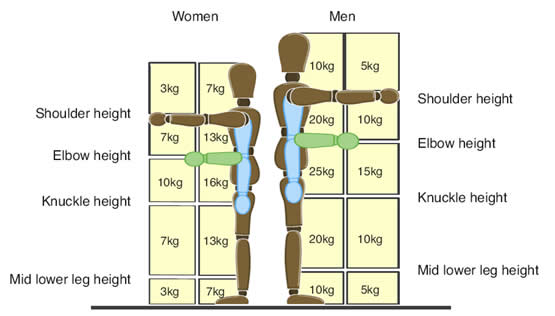

Manual Handling Guidelines

Weight Challenges

These loaded trays have been known in our experience to weigh as much as 35Kg, thus posing ergonomic issues for the operator in moving even a single tray to an intermediate transport trolley.

Consideration for Automation

It is not always suitable for the client to procure automated conveying lines due to the valuable floor space required which may be reserved for other processes and perhaps, ingress/egress of the people. The path from location A to point B may also not be straightforward.

Innovative Solution: PalPharma’s M7 Unit

Where automation is not feasible with regards to the above then PalPharma’s mobile M7 unit is then suited for such tasks as it has a drastically reduced risk of cross-contamination to other claimed ‘hygienic’ catalogue type trolleys. Furthermore, the company no longer has to worry about breaching legal manual handling regulations & operator downtime or insurance claims, etc.

Mitigating Risks

The risk from particle shedding, chemically reactive, porous materials have all been mitigated in the design. Suitable for the majority of client sporicidal sprays & cleaning agents. Combined with numerous ‘end effectors’ to suit all manner of cleanroom processes. It comes complete – as standard – with a battery-powered ‘end effector’, but compressed air-fed designs are also available for certain ATEX/IECex, etc areas. The machine can also be upgraded to suit chemically aggressive VHP gassing.

This product is not restricted to moving trays. The end effector can be changed over so that the movement of drums/kegs is made available with an adjustable gripper arm for varying diameters. Rotating them, charging via forward pour into a manway easing dispensing operations, decanting, docking a drum to a high containment isolator and many more operations are possible.

Image: M7 Drum/Keg Moving/Rotating End Effector