Here at Palamatic, we recognise more than most that when it comes to industrial operations, safety is the cornerstone of every successful venture. This is particularly pertinent to hazardous environments where the slightest misstep can lead to serious consequences, and ensuring the wellbeing of both personnel and processes is paramount. This is where ATEX compliance plays a pivotal role, offering assurance amidst the complexities of hazardous material handling.

With over 35 years of experience in materials and powder handling, Palamatic stands as a beacon of innovation, providing cutting-edge solutions that not only streamline operations but also prioritise safety in every step of the process.

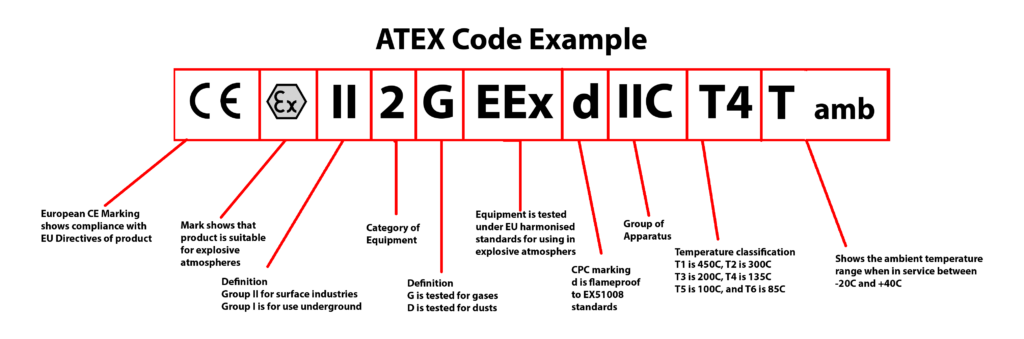

What is ATEX Compliance?

ATEX directives, originating from the European Union, lay down stringent regulations for equipment and protective systems intended for use in potentially explosive atmospheres. These directives aim to mitigate the risks associated with operating in such hazardous environments, ensuring that all equipment meets rigorous safety standards.

The Importance of ATEX Compliance in Hazardous Environments

In hazardous environments where flammable gases, vapours, liquids, combustible dust, or ignitable fibres are present, the risk of explosions and other incidents are high. ATEX compliance emerges as a critical safeguard, offering a structured framework to mitigate risks and ensure the safety of personnel and assets. Some reasons why adherences to ATEX directives is indispensable in hazardous environments include:

Prevention of Explosive Atmospheres

ATEX directives mandate the implementation of measures to prevent the formation of explosive atmospheres. By identifying potential sources of ignition and implementing appropriate controls, ATEX compliance significantly reduces the likelihood of explosive events, safeguarding both personnel and infrastructure.

Protection Against Ignition Sources

Hazardous environments are often rife with potential ignition sources, ranging from electrical equipment to mechanical sparks. ATEX compliant equipment and protective systems are designed to minimise the risk of ignition, thereby preventing the initiation of explosive reactions and mitigating the associated hazards.

Enhanced Safety Measures

ATEX compliance entails rigorous safety standards encompassing the design, construction, and operation of equipment and facilities in hazardous areas. From robust material selection to stringent testing protocols, ATEX compliant solutions prioritise safety at every stage, fostering a secure working environment for all stakeholders.

Legal and Regulatory Obligations

Compliance with ATEX directives isn’t just a matter of best practice—it’s a legal requirement in many jurisdictions. Non-compliance can lead to severe penalties, including fines, litigation, and even business shutdowns. By adhering to ATEX regulations, organisations demonstrate their commitment to safety and regulatory compliance, mitigating legal risks and liabilities.

Protection of Personnel and Assets

The primary objective of ATEX compliance is to safeguard human lives and protect valuable assets from the devastating consequences of explosions and fires. By investing in ATEX compliant equipment and adherence to safety protocols, organisations prioritise the wellbeing of their workforce and minimise the potential for costly damage to property and infrastructure.

Risk Mitigation and Business Continuity

Implementing ATEX compliant measures isn’t just about averting immediate dangers—it’s also about ensuring the continuity of operations in the face of potential hazards. By proactively addressing risks and vulnerabilities, organisations enhance their resilience to external threats, safeguarding business continuity and preserving their reputation in the marketplace.

Palamatic’s Commitment to Safety

At Palamatic, safety isn’t merely a procedural requirement—every product and service we offer is meticulously crafted with the utmost attention to safety, ensuring that our clients operate in environments that prioritise the wellbeing of their personnel andassets.

Our material handling solutions are meticulously crafted and can be configured to adhere to both ATEX and GMP standards.

Industrial Vacuum Lifters

Palamatic’s Industrial Vacuum Lifters epitomise innovation and safety in material handling. Designed with ATEX compliance in mind, these lifters are engineered to assist operators in the repetitive lifting of various materials. By harnessing the power of vacuum technology, these lifters not only enhance productivity but also minimise the risk of accidents and injuries, thereby creating a safer working environment for all.

Hygienic Stainless-Steel Range

For industries that demand stringent cleanliness standards, Palamatic offers a Hygienic Stainless-Steel Range. Crafted specifically for sectors like Biotech, Food Processing, and Pharmaceuticals, these vacuum lifters boast ATEX and GMP compliant solutions. With FDA-approved materials and special filtration systems, they ensure both safety and sanitation in sensitive environments, safeguarding against contamination and ensuring product integrity.

Dust-Free Sack Opening Systems

Cross-contamination and dust exposure pose significant risks in industries handling a wide array of materials. Palamatic’s Dust-Free Sack Opening Systems provide a COSHH-compliant solution, safeguarding operators from potential hazards while maintaining product integrity. Available in various configurations and ATEX classifications, these systems offer efficiency and safety hand in hand, ensuring a clean and safe working environment.

Crane Systems

Supporting the backbone of material handling operations, Palamatic’s Crane Systems provide robust overhead support for vacuum lifters. Engineered for durability and minimal maintenance, these systems ensure the safe and efficient operation of lifting equipment, further enhancing workplace safety. Whether it’s an H-Style Gantry Crane system for larger working areas or a Swing Jib Crane system for more confined spaces, Palamatic offers solutions tailored to meet the unique needs of each client.

Bespoke Material Handling Equipment

Recognising that every industry has its unique challenges, Palamatic goes beyond standard solutions. With a commitment to customisation, we offer bespoke material handling equipment tailored to the specific needs of each business. This collaborative approach ensures that safety and efficiency remain at the forefront of every solution, allowing clients to optimise their operations while adhering to stringent safety standards.

Trust Palamatic for ATEX Compliant Solutions

In hazardous environments, adherence to safety standards isn’t optional—it’s imperative. Our ATEX compliant solutions not only meet regulatory requirements but also provide peace of mind, allowing industries to focus on what they do best while safeguarding their most valuable assets. With Palamatic as your trusted partner, you can navigate the complexities of hazardous material handling with confidence, knowing that safety always comes first.

For further information and guidance regarding our ATEX compliant solutions, contact us today.