We recognise the significance of complying with the UK manual handling regulations to ensure the safety and well-being of both employees and products.

To minimise the risks associated with manual handling, it is crucial to provide proper training and use appropriate handling equipment. The training should cover safe lifting techniques, ergonomic principles, risk assessment, and the proper use of handling aids such as lifting equipment and personal protective gear.

We provide a range of innovative material handling solutions designed to enhance safety and efficiency in manual handling tasks. From Industrial Vacuum Lifters to Gantry Cranes and Dust-Free Sack Opening Systems, our products are engineered to streamline material handling processes while reducing the risk of injury. By understanding the nature of manual handling tasks and implementing appropriate measures, employers can create safer and healthier workplaces for their employees.

What is Manual Handling?

Manual handling refers to the process of transporting or supporting loads by hand or bodily force. This can include lifting, lowering, pushing, pulling, carrying, or moving objects, materials, or people. Manual handling tasks are ubiquitous across various industries and workplaces, from manufacturing and construction to healthcare and retail.

Key Aspects of Manual Handling

Lifting

Lifting is one of the most common manual handling tasks. It involves raising a load from a lower to a higher position, typically using the arms and back muscles. Improper lifting techniques can lead to strain and injury.

Lowering

Lowering is the opposite of lifting and involves bringing a load from a higher to a lower position. Care must be taken to control the descent of the load to prevent sudden movements that can cause injury.

Pushing and Pulling

Pushing and pulling tasks require applying force to move objects horizontally. These tasks often involve handling carts, trolleys, or other wheeled equipment. Proper posture and technique are essential to minimise muscle and joint strain.

Carrying

Carrying involves transporting a load while maintaining control and balance. It may involve holding objects in the hands, on the shoulders, or against the body. Correct weight distribution and grip strength are crucial to prevent accidents and injuries.

Risks Associated with Manual Handling

Manual handling tasks pose various risks to workers, including:

Musculoskeletal Injuries: Strain, sprains, and musculoskeletal disorders (MSDs) can result from lifting, carrying, or moving heavy loads incorrectly or repetitively.

Accidents: Poor handling techniques can lead to accidents such as slips, trips, and falls, causing injuries not only to the individual handling the load but also to others nearby.

Fatigue and Stress: Manual handling tasks can be physically demanding and mentally exhausting, leading to fatigue and stress if not managed properly.

Understanding Manual Handling Regulations

In the UK, manual handling regulations are governed primarily by the Manual Handling Operations Regulations 1992 (MHOR). These regulations protect workers from the risks associated with manual handling tasks, such as lifting, carrying, pushing, or pulling heavy loads.

Key Components of Manual Handling Regulations

Risk Assessment

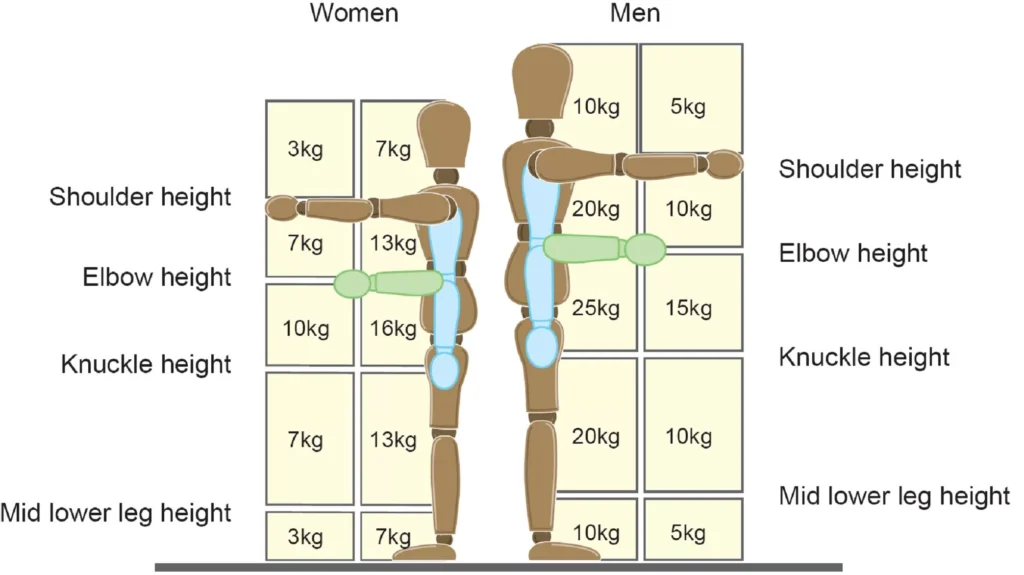

Under the MHOR, employers are required to conduct thorough risk assessments of manual handling tasks. Identify tasks that involve manual handling and assess the associated risks, considering factors such as load weight, frequency of handling, and ergonomic conditions.

Training and Education

The Manual Handling Operations Regulations 1992 emphasises the importance of proper training for employees involved in manual handling tasks. Provide training on safe lifting techniques, ergonomic principles, and the proper use of handling equipment to minimise the risk of injury.

Use of Handling Equipment

Employers are encouraged to utilise appropriate handling equipment to reduce the risk of injuries associated with manual handling. Palamatic offers a range of manual handling systems designed to streamline material handling processes while ensuring safety and efficiency.

Compliance with Regulations

Stay updated with the UK’s MHOR and other relevant regulations and standards. Ensure that your handling equipment meets regulatory requirements and undergoes regular inspections and maintenance to remain compliant.

What is a Manual Handling Risk Assessment?

A manual handling risk assessment is a systematic process of identifying, evaluating, and mitigating the risks associated with manual handling tasks in the workplace. It involves assessing various factors that can contribute to the likelihood of injury or harm while lifting, carrying, pushing, or pulling objects or loads.

Key Components of a Manual Handling Risk Assessment

Identification of Manual Handling Tasks

The first step in conducting a risk assessment is to identify all manual handling tasks carried out in the workplace. This includes tasks involving lifting, lowering, pushing, pulling, and carrying loads of varying weights and dimensions.

Identification of Hazards

Once manual handling tasks are identified, the next step is to identify potential hazards associated with each task. Hazards may include heavy loads, awkward postures, repetitive movements, poor ergonomics, and environmental factors such as slippery floors or restricted spaces.

Assessment of Risk Factors

Assess the risk factors associated with each identified hazard. Consider factors such as the weight and size of the load, the frequency and duration of handling, the posture adopted during handling, and the physical capabilities of the individuals involved.

Evaluation of Risk Severity

Evaluate the severity of the identified risks based on their potential to cause harm or injury. Consider the likelihood of accidents or injuries occurring and the potential consequences, such as musculoskeletal disorders (MSDs), strains, sprains, or accidents.

Implementation of Control Measures

Based on the risk assessment findings, implement control measures to reduce or eliminate the identified risks. This may include redesigning work processes, providing training on safe handling techniques, using mechanical aids or handling equipment, and implementing ergonomic improvements.

Importance of Conducting a Manual Handling Risk Assessment

Prevention of Injuries

A thorough risk assessment helps identify hazards and implement measures to prevent injuries and accidents associated with manual handling tasks.

Legal Compliance

In many countries, including the UK, employers have a legal obligation to conduct risk assessments under health and safety regulations. Failure to do so can result in legal consequences and penalties.

Promotion of Safety Culture

By involving employees in the risk assessment process, employers demonstrate their commitment to workplace safety and foster a culture of safety awareness and participation.

Palamatic Solutions for Manual Handling Compliance

Industrial Vacuum Lifters

Our industrial vacuum lifters are designed to assist operators with repetitive lifting tasks while minimising the risk of accidents and injuries. Compliant with UK regulations and available with options for various industries, these lifters are a proven solution for safe and efficient material handling.

Hygienic Stainless Steel Vacuum Lifters

Specifically designed for clean areas in industries such as biotech, food processing, and pharmaceuticals, our hygienic stainless steel vacuum lifters ensure the safe handling of delicate materials and food-grade substances. Compliant with UK regulations and featuring special filtration systems, these lifters prioritise cleanliness and safety.

Dust-Free Sack Opening Systems

Our dust-free sack opening systems provide a COSHH-compliant solution for environments handling sensitive materials. Compliant with UK regulations, these systems minimise dust exposure and cross-contamination risks while enhancing safety and productivity in various industries.

Gantry Crane Systems

Palamatic offers a range of crane systems to complement our vacuum lifters, providing overhead support for handling tasks. Whether you need an H-Style Gantry Crane System for larger working areas or a Swing Jib Crane System for production environments, our solutions are designed for durability, efficiency, and compliance with UK regulations.

Stay Compliant with Palamatic

Navigating manual handling regulations in the UK is essential for maintaining a safe and compliant workplace. By conducting risk assessments, providing proper training, utilising appropriate handling equipment, and staying updated with regulations such as the Manual Handling Operations Regulations 1992, you can ensure the well-being of your employees and the efficiency of your operations.

Palamatic is your trusted partner in achieving compliance with our innovative material handling solutions designed to meet the highest standards of safety and efficiency.