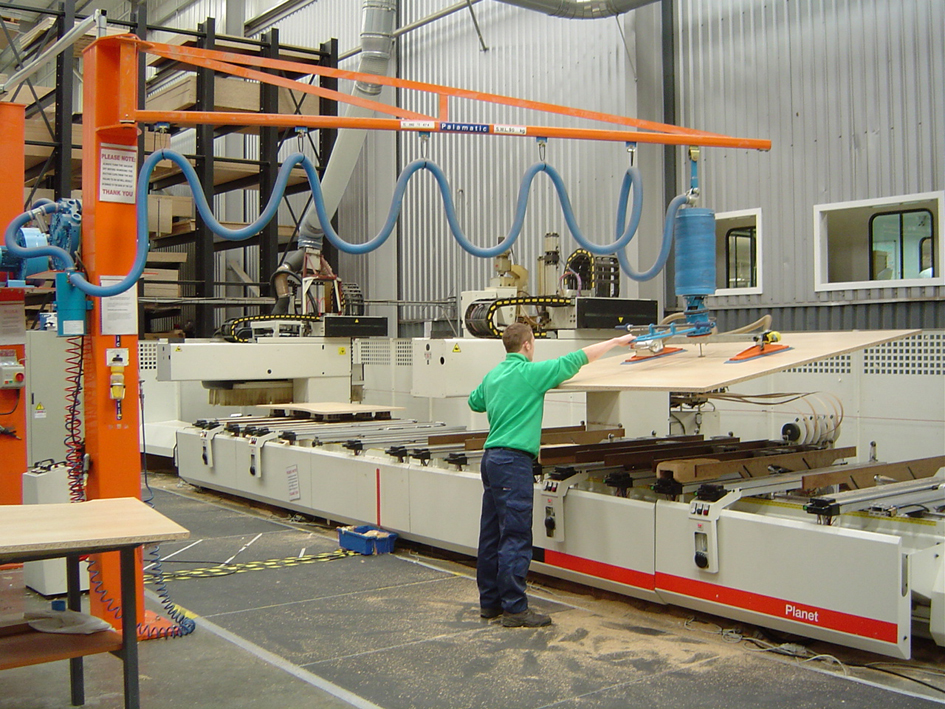

At Palamatic, we leverage over 35 years of expertise to provide cutting-edge solutions that enhance safety and productivity. Ensuring workplace safety and that the best practices are being upheld is essential for protecting your workforce, assets and prevent accidents and injuries.

Helping uphold correct workplace safety and best working practices, our Industrial Vacuum Lifters are designed to minimise operational hazards, protect operators, and streamline processes; all while offering ergonomic support. To ensure that your vacuum lifting equipment is performing at its best, it’s important to uphold the following practices:

Understanding Vacuum Lifting Equipment

Before operating a Palamatic Industrial Vacuum Lifter, it is crucial to understand its components and functionality. Familiarise yourself with the following parts:

Vacuum Pump

Generates the suction necessary for lifting objects. Ensure it is regularly maintained and operating at optimal efficiency.

Suction Pad/Gripping Device

Attaches to the object being lifted. Choose the appropriate pad size and type for the material being handled.

Control Mechanism

Allows the operator to manage the lifting process. Properly adjust the controls for ergonomic use.

Pre-Operational Checks

Performing routine checks before using the equipment can prevent accidents and ensure efficient operation.

Inspect the Suction Pad

Ensure it is clean, free from damage, and suitable for the object to be lifted.

Check Connections

Verify that all hoses and connections are secure and free from leaks.

Test the Vacuum Pump

Ensure it is operating correctly and achieving the required vacuum level. Check for unusual noises or vibrations.

Ergonomic Considerations

Ergonomics play a vital role in reducing strain and injury. Our vacuum lifters are designed to assist with repetitive lifting tasks, enhancing operator comfort and safety.

Adjust the Control Mechanism

Position it at a comfortable height and angle for the operator to reduce strain.

Maintain Proper Posture

Encourage operators to stand upright, keep their backs straight, and use their legs when lifting.

Use Assistive Devices

Where possible, use additional ergonomic tools or supports to aid in handling tasks.

Safe Lifting Practices

Adhering to safe lifting practices is essential to prevent accidents and injuries.

Use the Right Suction Pad

Ensure the pad is appropriate for the object’s size, shape, and weight.

Centre the Load

Position the suction pad at the centre of the object to maintain balance and stability.

Lift Smoothly

Avoid sudden movements; lift and lower objects smoothly to prevent shifting or falling. Ensure the path is clear of obstacles.

Compliance with Safety Standards

Ensure that all operations comply with relevant safety standards, such as LOLER for lifting equipment, ATEX for explosive atmospheres and GMP for good manufacturing practices.

Follow Manufacturer Guidelines

Adhere strictly to the instructions provided by Palamatic.

Regular Inspections

Schedule routine inspections to ensure ongoing compliance and safety. Document and address any identified issues promptly.

Safety Audits

Conduct regular safety audits to identify potential risks and implement corrective actions.

Dust Control Measures

In environments where dust exposure is a concern, implement appropriate dust control measures.

Use Dust-Free Systems

Our Dust-Free Sack Opening Systems protect operators from dust exposure and prevent cross-contamination.

Regular Cleaning

Ensure all equipment, especially suction pads and filters, are cleaned regularly to maintain optimal performance and hygiene.

Monitor Air Quality

Use air quality monitoring devices to ensure a safe working environment.

Training and Empowering Employees

Comprehensive training ensures that operators are proficient in using the equipment safely.

Provide Hands-On Training

Conduct practical training sessions for all operators, covering all aspects of equipment use, maintenance, and emergency procedures.

Certify Competency

Ensure operators hold relevant certifications such as LOLER and IPAF and offer refresher courses regularly.

Encourage Reporting

Create an environment where employees feel comfortable reporting safety concerns or equipment issues without fear of reprisal.

Regular Maintenance and Support

Maintaining the equipment is crucial for safe and efficient operation.

Schedule Regular Maintenance

Follow a maintenance schedule to keep the equipment in peak condition. Include checks for wear and tear, lubrication, and electrical integrity.

Use Genuine Spare Parts

Ensure that any replacements are genuine Palamatic parts to maintain the integrity and performance of the equipment.

Seek Expert Support

Contact our support team for any maintenance or operational issues. Utilise our after-sales services for ongoing support and spare parts availability.

Trust Palamatic to Enhance Your Workplace Operations

By following these best practices, you can ensure the safe and efficient operation of your vacuum lifting equipment. Our commitment to safety, ergonomics, and innovation underpins our solutions, helping you to minimise operational hazards and enhance productivity.

For further assistance or to enquire about our state-of-the-art material handling solutions, please get in touch with our experts today.